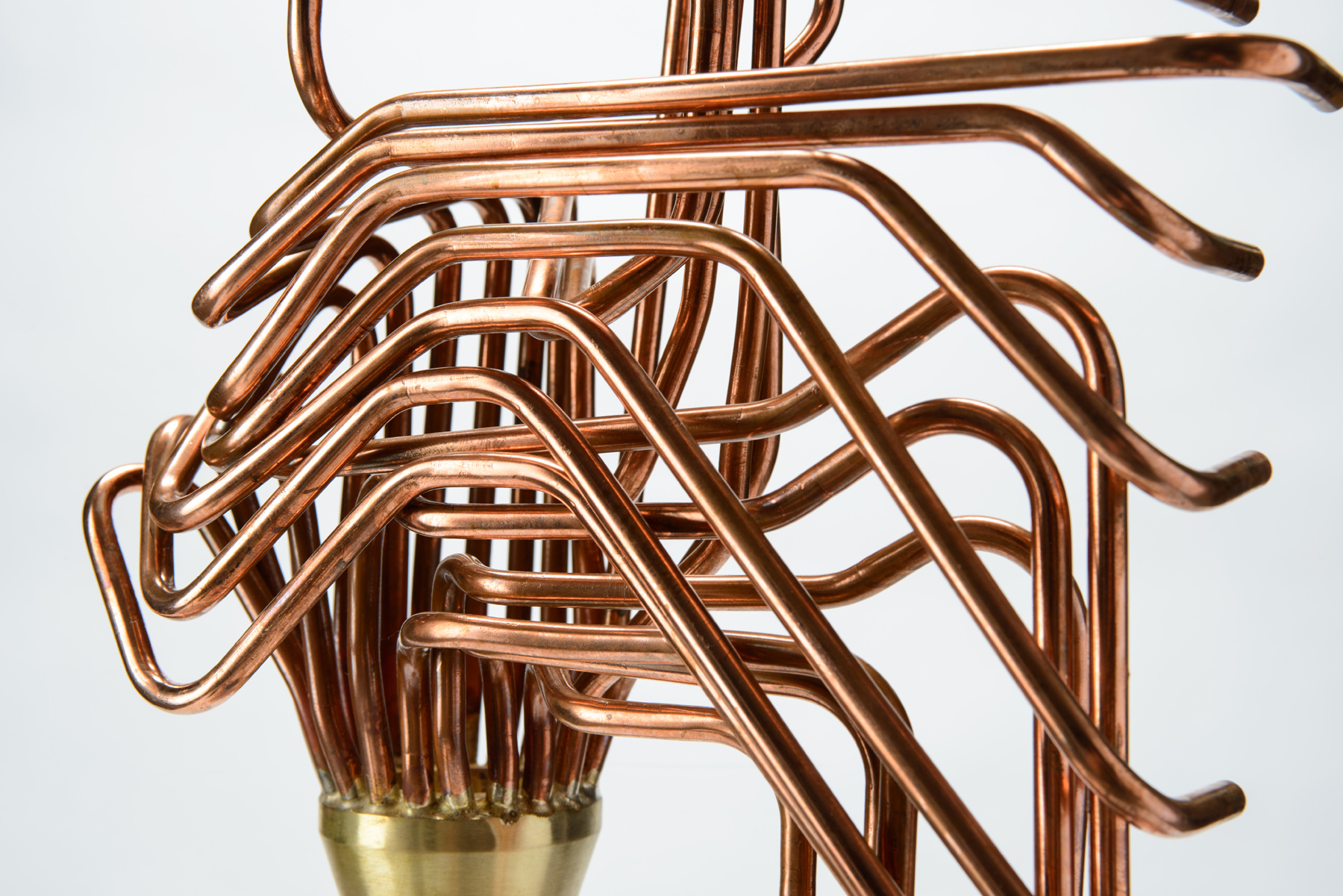

At E&M, where precision meets innovation in copper tube bending. As industry leaders, we take pride in our unparalleled capabilities to shape copper tubes with utmost accuracy and flexibility. Our state-of-the-art bending technology, coupled with a team of skilled operators, allows us to create intricate and customized designs that meet the unique specifications of our clients.

Whether it’s for HVAC systems, plumbing applications, or other custom fabricated products, our copper tube bending expertise ensures that each bend is executed with precision, maintaining the structural integrity of the material.

From prototypes to large-scale production, E&M sets the standard for excellence in the world of metal fabrication. Our tube bending capabilities spans from as little as capillary tube diameters 0.090" to 1-3/8" outside diameter

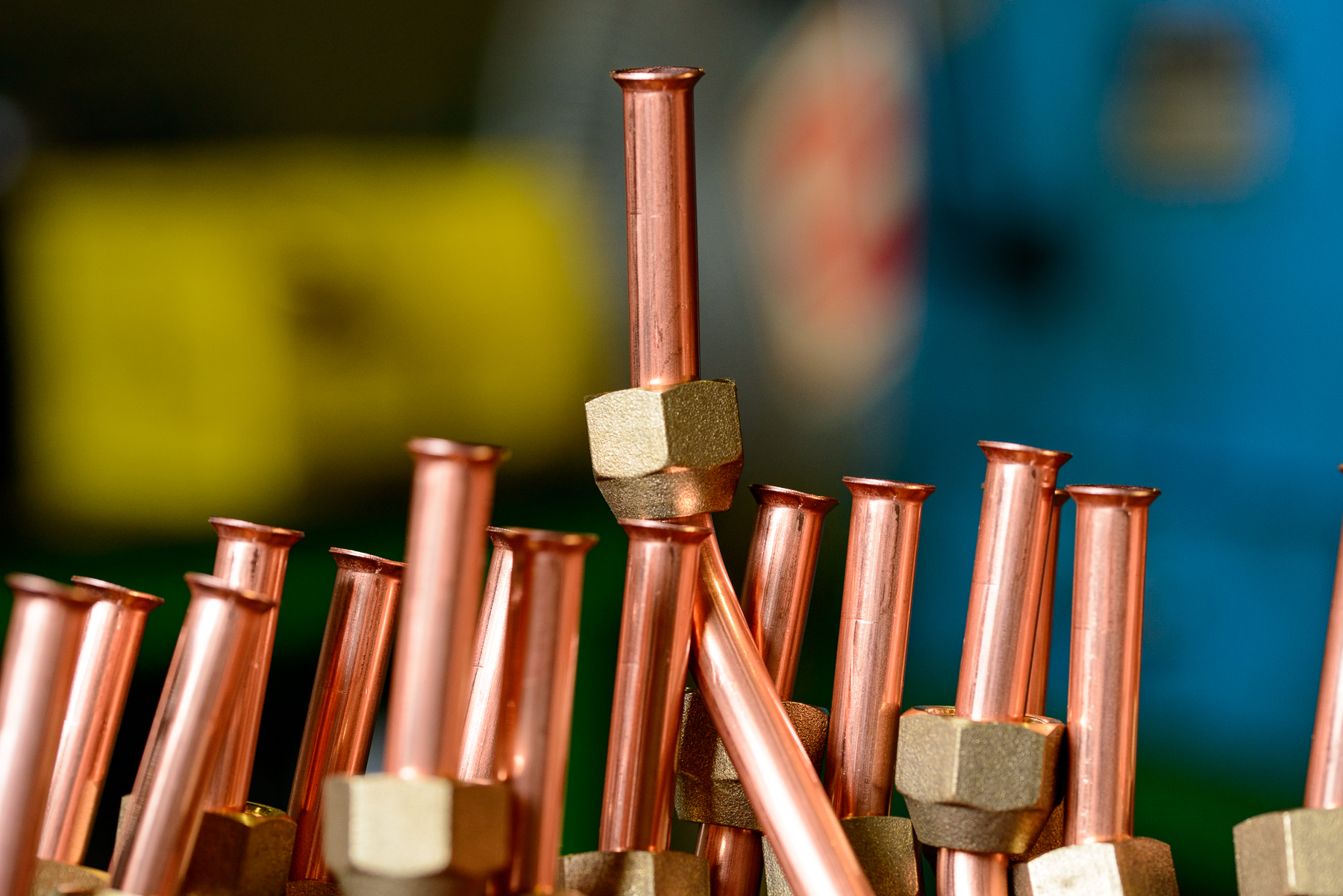

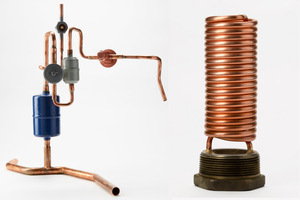

E&M Copper Products Inc. stands as a trusted manufacturer in brazing and soldering, offering unparalleled expertise and precision in crafting both simple and intricate brazed assemblies. Our skilled team leverages years of experience and advanced techniques to deliver high-quality results that meet the stringent standards of various industries.

Expertise in Complex Assemblies: Whether it’s a straightforward task or a highly intricate assembly, our team excels in managing projects of all complexities with meticulous attention to detail.

Advanced Techniques: Utilizing state-of-the-art equipment and cutting-edge brazing and soldering methods, we ensure robust and reliable joints that withstand the demands of diverse applications.

Wide Range of Materials: We work with a variety of metals, including copper, brass, and stainless steel, to provide versatile solutions tailored to the specific needs of each project.

Custom Solutions: Our approach is highly customized, allowing us to create bespoke brazed assemblies that align perfectly with our clients’ specifications and performance requirements.

Our brazing and soldering services cater to a broad spectrum of industries, including HVAC, automotive, aerospace, and more, demonstrating our versatility and commitment to serving diverse market needs.

At E&M Copper Products Inc., we specialize in precise copper tube drilling, offering regular hole drilling, punching holes, and collar hole drilling. Our advanced equipment and skilled team ensure accurate and consistent results for various applications.