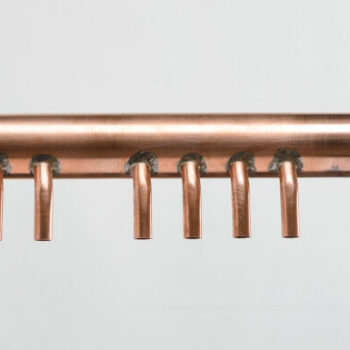

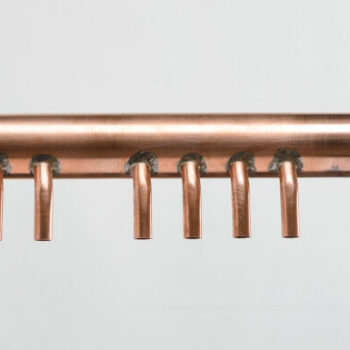

ACR systems are a key part of new buildings climate and comfort control. Heating, ventilation and air conditioning (HVAC) systems help to control the climate and keep occupants comfortable by regulating the temperature and air flow. HVAC systems are also important to occupants’ health, because a well-regulated and maintained system will keep a home or business free from mold and other harmful organisms. So here at E&M Copper Products we are committed to serving the HVAC industries with the highest quality components.

Through hard work and a strong understanding of what our customers’ needs are we are able to produce the quality components they require to manufacture the finished product. We strive to be on time and at a competitive price.

E&M Copper Products has the ability to make unique parts for our customers, through blueprint or sample. We will work tirelessly for you to ensure the right outcome. We can manufacture small custom runs or larger blanket orders; our experienced staff is open and available to assist you in your manufacturing needs.

E&M Copper Products reach is worldwide, having parts that reach across Canada, the United States, Europe and other parts of the world. Being ISO certified makes us the company able to uphold the automotive industry standards.

E&M Copper Products has been producing components for the plumbing industry since 1984 and is proud to be part on an industry that is the substantial part of every developed economy.

Our CNC bending capability enables us to provide complex components while maintaining accuracy and repeatability.

CAPABILITIES

We believe in more efficient methods of manufacturing through the ability to assist customer requirements. From sample to print, we can take on any project big or small.

Over the years, we have faced many challenges from which we draw our experience; this has enabled us to improve our manufacturing methods.

- Tube Coiling

- End Forming

- Hole Forming

- Brazing

- Drilling

- Cutting

- Custom Tube Fabrication

- Saddle

- Expanded

- Reduced

- Flanged

- Closed

- Flared

- Double Flared

- Custom Formed

- Swage

- Punched

- Drilled

- Extruded (T-drill)

- Copper to Copper

- Copper to Brass

- Copper to Steel

- Sub-assembly and full assemblies

- Nitrogen purging

- Copper

- Brass

- Aluminum

- Stainless Steel

- Cold Rolled Steel

- Air Leak Testing